What is the HFC Phase-down?

Hydrofluorocarbons (HFCs), are a synthetic greenhouse gas widely used in heating and cooling applications and have been identified as contributing to worldwide climate change.

In October 2016, New Zealand was among the 197 Parties to the Montreal Protocol on Substances that Deplete the Ozone Layer (the Montreal Protocol) that adopted an amendment in Kigali, Rwanda to phase down HFCs worldwide. The Kigali Amendment puts in place a worldwide phase down of the production and consumption of HFCs.

How does the phasedown work?

The controls on HFCs under the Kigali Amendment are on the importation and exportation of bulk HFCs.

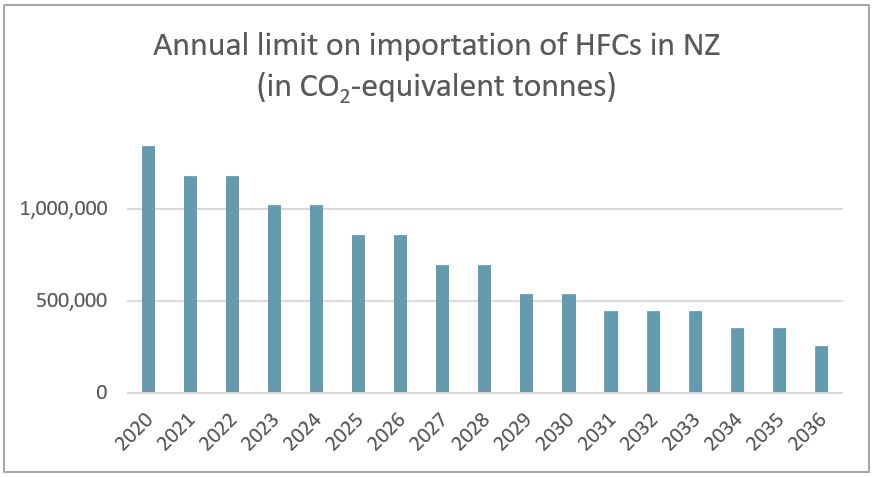

Under the Amendment, each country needs to limit its annual consumption of HFCs to within the cap/upper limit.

New Zealand’s phase down committments.

New Zealand suppliers of HFC refrigerant operate on a permitting scheme that has allocated amounts dependent on there historical importation and limits who can bring HFC refrigerants into the country. Each permit holder is given a maximum carbon dioxide equivalent in tonnes of HFCs they can bring into New Zealand for each calendar year, and any other import conditions, though it does not specify the type of HFC gas that should be imported. As the amount of HFC imported is not based on kgs but total emmisions the lower the GWP of the gases in a shipment, the larger the weight that can be shipped, as long as their combined CO2 equivalent mass is within the permit allocation.

What will that mean for my business?

Natural Refrigerant Systems

Investment in commercial refrigeration has historically been in direct systems, due to lower capital costs, widely understood and readily available equipment and the comparative safety of synthetic refrigerants.

Secondary systems – where cooling is achieved by a smaller primary refrigeration circuit cooling a fluid circulating around the refrigerated space, have typically only been available to larger cool stores and food processors, providing higher levels of safety and reliability in cool store operation.

However, with the potential impacts of the HFC phase down, advances in technology have enabled secondary systems to become more commonplace across a variety of industries and applications to take advantage of the using less refrigerant through smaller primary refrigerant charge design.

The next generation in secondary systems – advanced secondary systems.

Through leading design and technology, the development of advanced secondary systems using natural refrigeration provides companies with a competitive advantage through superior performance and operational efficiencies, including energy use reductions and improved reliability, while ensuring safety and compliance with regulatory requirements.